Aluminum Foils

A leading Chinese aluminum foil manufacturer typically operates integrated facilities, controlling the process from smelting and casting to hot rolling, cold rolling, and final annealing. This vertical integration allows for strict quality control and cost-effectiveness.

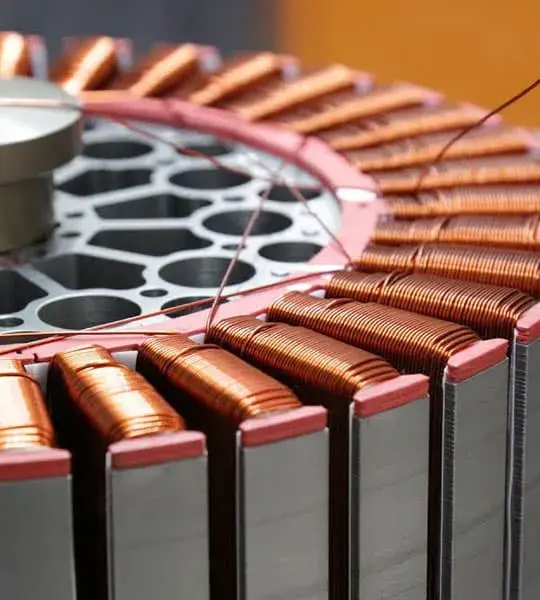

The core components of transformer aluminum foil are: high-purity, high-conductivity aluminum alloys, mainly 1050, 1060, 1070, 1350, etc.

Applications

Aluminum foils are particularly widely used in dry-type transformers, rectifier transformers, reactors, and low-voltage, high-current windings of transformers. High conductivity is a primary goal likes grade 1070 and grade 1060. Their high aluminum content (≥99.7%) and minimal impurities provide optimal conductivity, effectively reducing resistive losses.

Capacitors: They are used as electrode materials, utilizing their high conductivity and large surface area.

Lithium Batteries: china aluminum foil are used as positive electrode current collectors in lithium-ion batteries. Power batteries, in particular, place extremely high demands on the thickness, strength, and surface quality of aluminum foil.

Cable Shielding: They are used as shielding layers for communication cables and coaxial cables, protecting signal transmission from external electromagnetic interference.

Heat Exchangers: Ultra-thin fins are used in heat exchangers in automotive and household air conditioners, owing to their excellent thermal conductivity and lightweight design.

Advantages:

- Lightweight, significantly reducing equipment weight

- Low cost, significant economic benefits

- Excellent heat dissipation (“surface heat conduction” effect)

- High space utilization (high fill factor)

- Excellent mechanical strength and short-circuit resistance

- Simplified manufacturing process, improved consistency

Compared with “Copper”

| Features | Description |

|---|---|

| Cost | Raw material costs are significantly lower than copper, resulting in high overall economic benefits. |

| Weight | Lightweight, making it easy to transport and install. |

| Heat Dissipation | The “surface heat conduction” effect surpasses the “point heat conduction” of round wire, resulting in excellent heat dissipation. |

| Mechanical Strength | The overall rigid structure provides strong short-circuit current resistance. |

| Space Efficiency | The high fill factor allows for a more compact design. |

| Electrical Conductivity | Aluminum’s electrical conductivity is approximately 61% of copper’s, but current carrying requirements can be met by increasing the cross-sectional area. |

LP Industry is china aluminum foil supplier, we provide wholesale aluminum foils. If you have any questions about aluminum strips, you can ask us.

Inquiry Now

Freely Send your requirement list to LP Industry.